Capricorn PFTE Bowden Tube – XS Series (100cm) ID1.9mm OD4.0mm

9,88€

Guaranteed to always be the right diameter, and perfectly round. Print flexible filaments without the binding up that happens with over-diameter tubes. Each meter of tubing comes with one Capricorn sticker to decorate your printer.

Some History…

Our XS Series of Professional Grade Bowden Tubing is made from the highest quality PTFE. Our secret blend of high lubricity additives turns it a deep blue color.

In 2016 we developed the XS (eXtra Slippery) formula of high lubricity additives combined with smaller inner diameter, 1.85mm, in order to print flexible filaments on a RostockMAX. Beta testers quickly discovered that it allowed them to lower retraction as well, which has proven to be an even bigger selling point.

High Lubricity Additives make our XS Series tubing the lowest friction Bowden tubing on the market. Less friction means more responsiveness, less retraction, more accurate prints, less slippage, wear, and tear on the extruder, and less clogging when printing chunky filaments such as some woodfills or ironfills.

Lower retraction means time saved every time the extruder retracts. Over the course of a print, a few milliseconds here and a few there add up to a lot of time saved.

1.85mm Inner Diameter Reduces the “wiggle room,” or buckling, inside the tube, allowing you to print flexible filaments even on the longest Bowden systems. Most of our printer farm printers are RostockMaxV3s and Tevo Little Monsters.

High Temperature Resistance due to using only the highest quality PTFE. Our XS tubing will operate at even higher temperatures than our TL. See our Safety page for more details about high temperature printing.

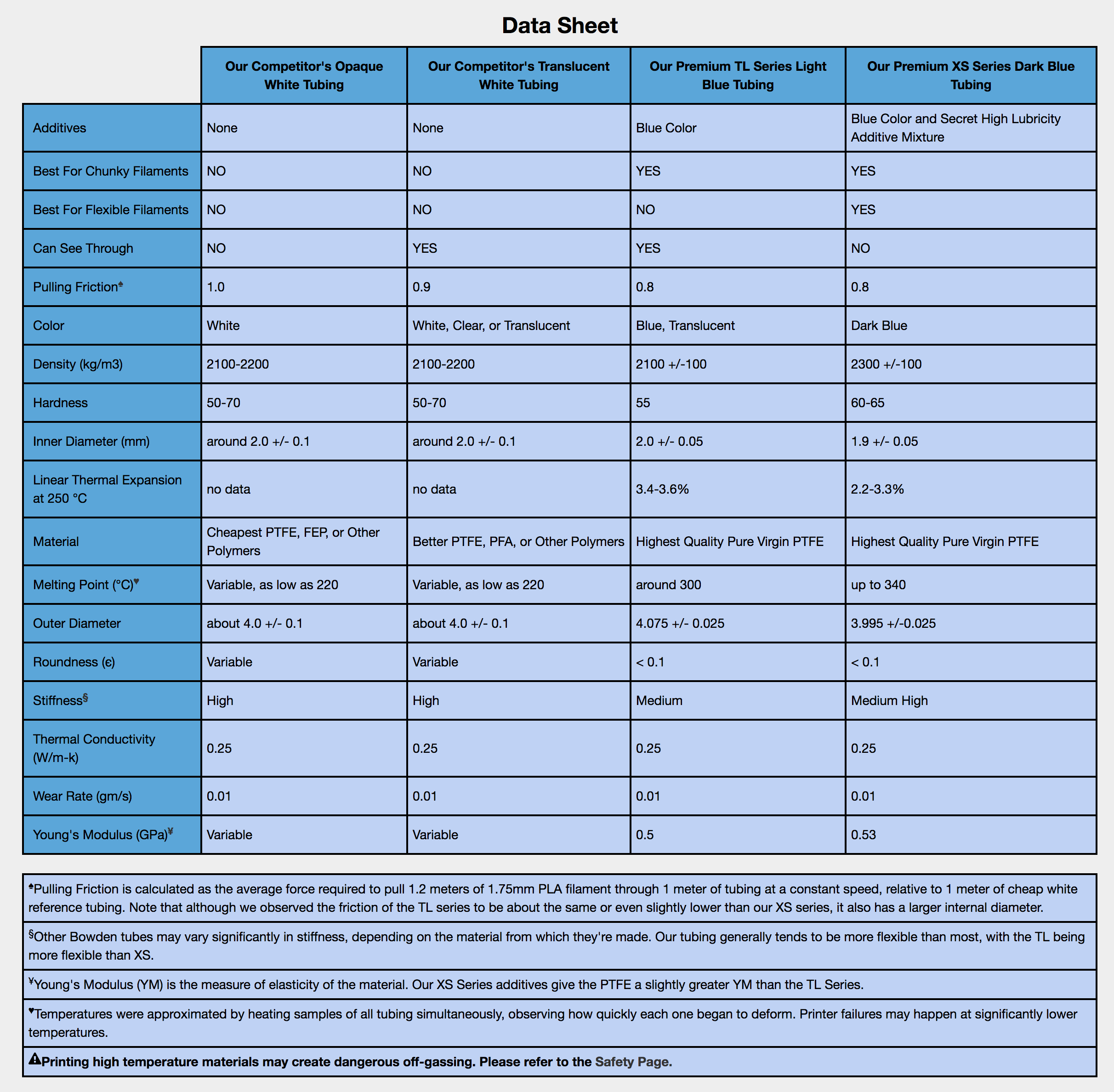

Data Sheet

| Additives | Blue Color and Secret High Performance Additive Mixture |

| Best For Chunky Filaments | Maybe |

| Best For Flexible Filaments | Yes |

| Can See Through | No |

| Pulling Friction♠ | 0.76 |

| Color | Dark Blue |

| Inner Diameter (mm) | 1.9 +/- 0.05 |

| Melting Point (°C)♥ | around 340 |

| Outer Diameter | 3.995 +/-0.025 |

| Young’s Modulus (GPa) | 0.532 |

Safety Precautions

PTFE is a flouropolymer, which exists in a state of matter known as a “glass.” This means it does not “melt,” like an ice cube, but rather slowly gets softer and softer as it gets warmer. Eventually it will either become a liquid, or catch fire.

Between room temperature and catching fire, all polymers emit tiny amounts of harmful gasses, known as “off-gassing.” The hotter they get, the more they will emit. See Chart*

Because our PTFE tends to have better temperature resistance (meaning it stays firmer at higher temperatures before significant deformation) than lower quality PTFE tubes, a number of users have reported success using it “inside the hot end.”

This is not something you should do willy-nilly. Just because it works, doesn’t mean there aren’t precautions to be taken. If you use PTFE, or any polymer for that matter, inside the hot end or anywhere excessive temperatures may be experienced, you will potentially create harmful off-gassing. Not only that, but the polymer you are extruding may be creating harmful gasses as well.

We strongly recommend running your 3D printer in a well ventilated area, away from children and pets.

In a classroom environment, we encourage printing with PLA, and staying away from higher temperature materials, whether you use our Bowden tubing or not.

Always have adult supervision when operating a 3D printer.

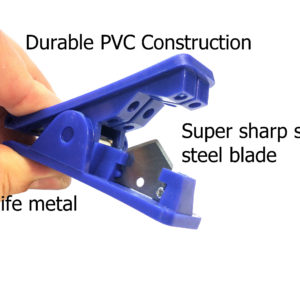

Keep razor-sharp Bowden tubing cutters out of reach of children.

Have fun, and stay safe out there!

| Weight | 1 kg |

|---|---|

| Dimensions | 2 × 1 × 2 cm |

Only logged in customers who have purchased this product may leave a review.

Related products

3D Printer Parts & Accessories

3D Printer Parts & Accessories

3D Printer Parts & Accessories

3D Printer Parts & Accessories

3D Printer Parts & Accessories

3D Printer Parts & Accessories

Capricorn PFTE Bowden Tube – TL Series (100cm) ID2.0mm OD4.0mm

3D Printer Parts & Accessories

3D Printer Parts & Accessories

Reviews

There are no reviews yet.