1.75mm EasyWood™ 3D Printer Filament – Cocconut

27,23€

In stock (can be backordered)

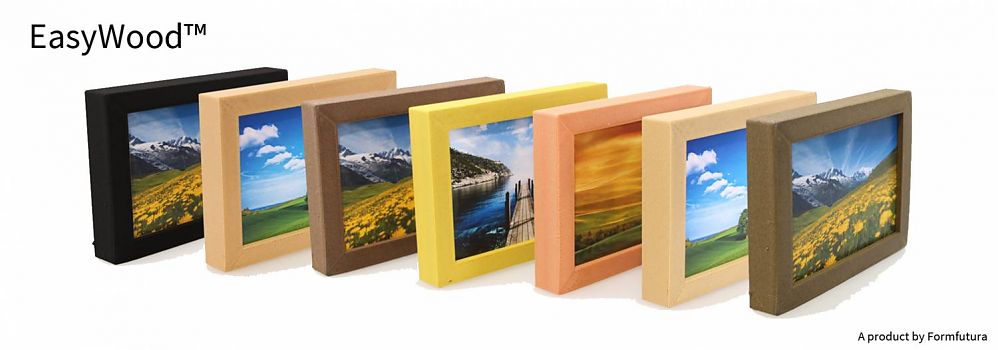

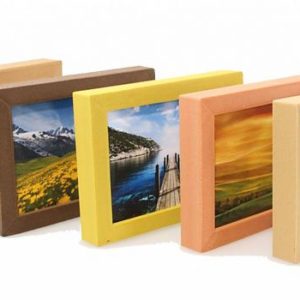

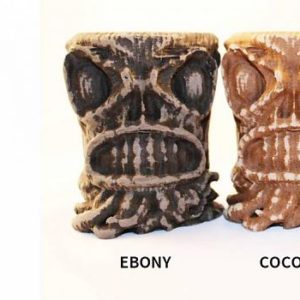

Imagine that you can 3D print objects with tropical hardwood…. Well now you can! EasyWood™ – Coconut is a revolutionary 3D printer filament. EasyWood™ looks, feels and smells like real wood. EasyWood™ – Coconut is a unique mixture of 40% grinded coconut particles in combination with the modified and proven easy-to-print binding polymers used for our EasyFil™ filaments. This extraordinary blend has resulted in a high-end and unsurpassed “easy to print” tropical hardwood filament. You will love the rough surface – with clearly noticeable coconut particles – of our spool-wrapped EasyWood™ – Coconut filament.

Being filled with a significant amount of grinded coconut particles gives EasyWood™ – Coconut some major advantages above other wood-filled filaments. First of all, coconut wood is a tropical hardwood which is a perfect substitute for traditional tropical hardwood and with that it does not affect the world’s rainforests. The wood from the actual coconut is very resistant to (salt) water, and because of its extremely low water absorption the wood from the coconut is hardly influenced by weather- and other nature conditions. This unique characteristic makes our EasyWood™ – Coconut filament significantly less sensitive to moisture than other wood-filled filaments.

EasyWood™ – Coconut has a beautiful dark tropical brown colour and has similar thermal properties to our EasyFil™ PLA. Because of its low shrinkage factor, EasyWood™ is nearly warp-free and therefore EasyWood™will not deform after cooling. Due to its low tendency to warp EasyWood™ can be printed without a heated print bed. If your printer is however equipped with a heated print bed we recommend to set your heat bed temperature to ± 35° to 60°C.

Next to its “easy to use” features, our Formfutura EasyWood™ filament range has an excellent roundness and very tight diameter tolerances, which makes this filament a perfect match with all common desktop 3D printers. Printing with EasyWood™ 3D printer filament will go very smoothly with basically all FFF/FDM technology based desktop 3D printers, such as:

- Ultimaker

- RepRap (Mendel, Huxley, Prusa)

- Solidoodle

- MakerBot (Replicator, Replicator 2, Replicator 2X)

- Leapfrog

- UP! Plus, Up! Mini

- AND MANY MORE….!

Our EasyWood™ does not contain any hazourdas, or chemical substances. EasyWood™ filaments are RoHS certified and REACH compliant.

Product details

Our EasyWood™ – Coconut 3D printer filament is wrapped on a ABS plastic spool which contains approximately 0.5kg of filament. Our spool-wrapped EasyWood™ filaments are packed in a silica sealed bag and come in a full colour printed cardboard box, which in turn is also shrink-wrapped in plastic. Please see below for more details with respect to the weight and packaging of our spool-wrapped EasyWood™ 3D printer filaments:

| Filament Net Weight: | ± 0.5 Kg |

| Spool Size (D x h): | 200 mm x 55 mm |

| Spool Hub Diameter: | 52 mm |

| Carton Box Size (L x W x H): | 200 mm x 200 mm x 60 mm |

| Packaged weight | 1 Kg |

For more technical specifications about our EasyWood™ 3D printer filament, please have a look at the ‘Technical Data’ PDF below.

General Tips & Tricks for printing with EasyWood™ filaments

The printing temperature guideline for printing with our EasyWood™ filament is approximately 210-220°C. As each desktop 3D printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. To obtain optimal results for your prints you need to take into account variables like your 3D printer’s nozzle diameter, your printing speed settings, and layer height.

EasyWood™ has similar thermal properties to our EasyFil™ PLA. Therefore it can be printed both with and without a heated print bed. However, if your desktop 3D printer does have a heated print bed it is recommended to set your print bed temperature to approximately 35° to 60° C.

A good first layer adhesion is of the utmost importance in obtaining the best results for your prints. Firstly make sure that you print bed is accurately levelled and clean. EasyWood™ sticks really well to an unprepared print bed. If you would however like to improve your first layer adhesion, then we recommend to prepare your print bed with blue masking tape, hairspray or our LokBuild surface. EasyWood™ sticks extremely well to this surface. Combined with StoneFill™ you can get astonishing landscapes and pieces of art like the ones featured in our gallery.

| Weight | 1 kg |

|---|---|

| Dimensions | 22 × 22 × 6 cm |

Only logged in customers who have purchased this product may leave a review.

Related products

1.75mm EasyWood™

1.75mm EasyWood™

1.75mm EasyWood™

1.75mm EasyWood™

1.75mm EasyWood™

1.75mm EasyWood™

Reviews

There are no reviews yet.